- Home Page

- Company Profile

-

Our Products

- Liquid Filling Machine

- Automatic Liquid Filling Machine

- Hair Oil Filling Machine

- Oil Filling Machine

- Vegetable Oil Filling Machine

- Coconut Oil Filling Machine

- Automatic Servo Filling Machine

- Shampoo Filling Machine

- Syrup Filling Machine

- PET Bottle Filling Machine

- High Speed Honey Filling Machine

- Automatic Four Head Filling Machine

- Automatic Six Head Volumetric Liquid Filling Machine

- Bottle Filling Machine

- Automatic Injectable Liquid Filling Machine

- Automatic Natural Juice Filling Machine

- Mustard Oil Filling Machine

- Edible Oil Filling Machine

- Juice Filling Machine

- Automatic Volumetric Liquid Filling Machine

- Flavored Milk Filling Machine

- Tin Oil Filling Machine

- Semi Automatic Liquid Filling Machine

- Automatic Volumetric Bottle Filling Machine

- Automatic Servo Bottle Filling Machine

- Automatic Liquid Filling Line

- Semi Automatic Cartonning machine

- Semi Automatic Servo Filling Machine

- Semi Digital Liquid Filling Machine

- Semi Automatic Hand Wash Filling Machine

- Electric Semi- Automatic Detergent Liquid Filling Machine

- Automatic Eight Head Volumetric Liquid Filling Machine

- Lubricant Filling Machine

- Cap Sealing Machine

- Automatic Multi Head Screw Cap Sealing Machine

- Automatic Single Head ROPP Cap Sealing Machine

- Semi Automatic Screw Cap Sealing Machine

- Automatic Single Head Vial Cap Sealing Machine

- Automatic Cap Sealing Machine

- Bottle Cap Sealing Machine

- Automatic Vial Capping Machine

- Automatic Pharmaceutical Capping Machine

- Automatic Multi Head ROPP Cap Sealing Machine

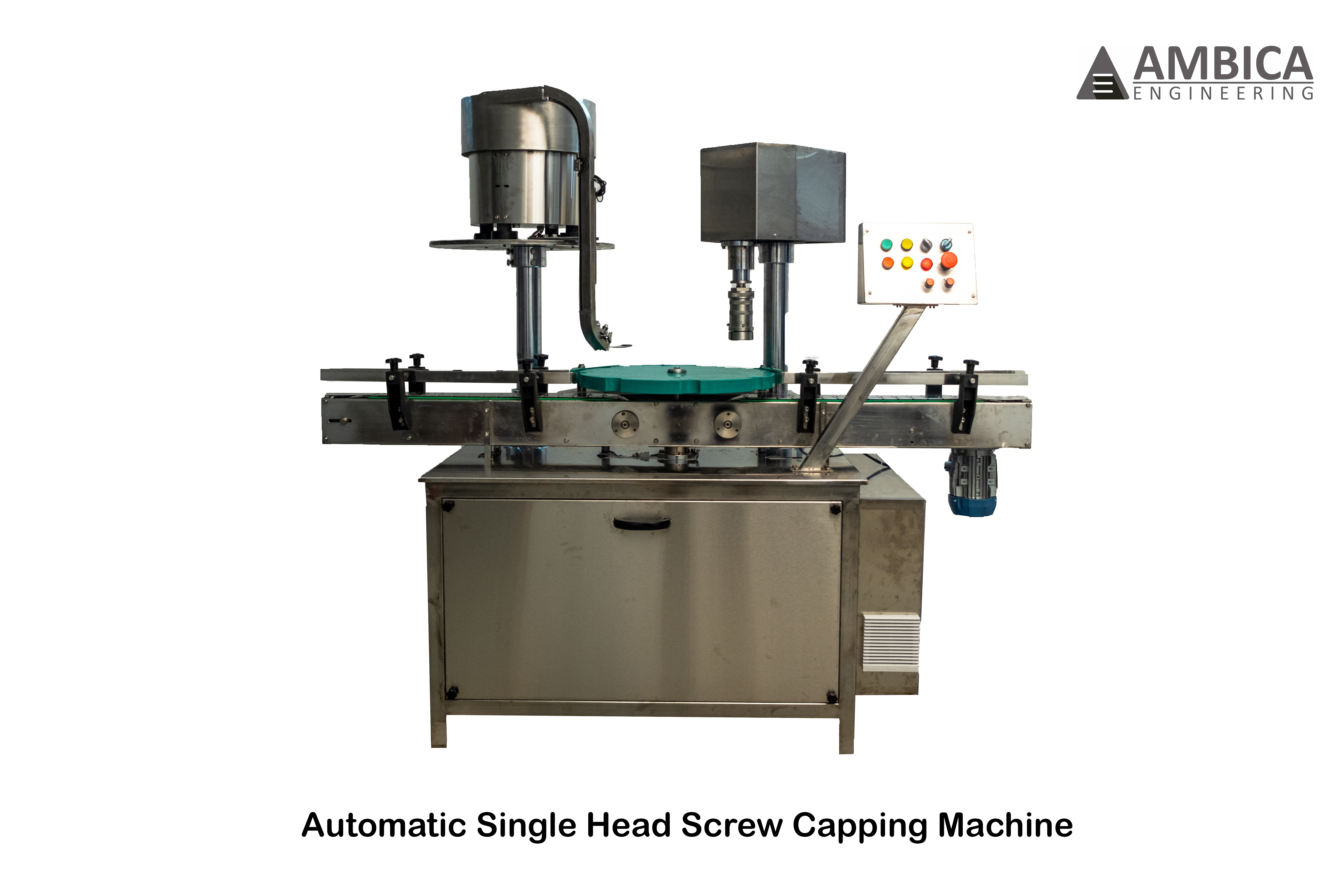

- Automatic Single Head Screw Cap Sealing Machine

- Automatic Screw Cap Sealing Machine

- Industrial Cap Sealing Machine

- Semi Automatic Capping Machine

- Automatic Induction Sealing Machine

- Semi Automatic ROPP Cap Sealing Machine

- Labeling Machine

- Fully Automatic Sticker Labeling Machine

- Fully Automatic Labeling Machine

- Automatic Double Sticker Labeling Machine

- Front Back Labeling Machine

- Round Bottle Sticker Labeling Machine

- Vial Sticker Labeling Machine

- Top Labeling Machine

- Wrap Around Labeling Machine

- Plastic Adhesive Labeling Machine

- Flat Bottle Labeling Machines

- Automatic Pharmaceutical Labeling Machine

- Ampoule Labeling Machine

- Automatic High Speed Ampoule Labeling Machine

- 2 Side Labeling Machine

- Square Bottle Labeling Machine

- Semi Automatic Bottle Labeling Machine

- Automatic Self Adhesive Sticker Labeling Machine

- Bottle Labeling Machine

- Sticker Labeling Machine

- Automatic Round Bottle Labeling Machine

- Servo Automatic Wrap Around Labeling Machine

- Automatic Sticker Labeling Machine

- Automatic Round And Flat Bottle Labelling Machine (Combo)

- Two Side Bottle Labeling Machine

- Manual Labelling Machine

- Stapper Automatic Wrap Around Labeling Machine

- Semi Automatic Sticker Labeling Machine

- Bottle Washing and Cleaning Machine

- Powder Filling Machine

- Packaging Machine

- Pharmaceutical Machine Spare Parts

- Expanding Shaft

- Inspection Table

- Turn Table

- Bottle Washing Machine

- Inner Plug Inserter

- Turntable Machine

- Pharmaceutical Liquid Filling LIne

- Industrial Conveyor

- Sealing Machine

- Bottle Packaging Machines

- Beverage Filling Machine

- Packing Conveyor

- Filling Machines

- Liquid Filling Machine

- Extra Links

- Contact Us

Automatic Multi Head Screw Cap Sealing Machine

320000 INR/Piece

Product Details:

- Power 220 Volt (v)

- Packaging Speed 60 Pieces/Minute

- Voltage 220 Volt (v)

- Accuracy 99 %

- Condition New

- Weight 800 Kilograms (kg)

- Type Automatic

- Click to View more

X

Automatic Multi Head Screw Cap Sealing Machine Price And Quantity

- 320000 INR/Piece

- 1 Piece

Automatic Multi Head Screw Cap Sealing Machine Product Specifications

- 220 Volt (v)

- 60 Pieces/Minute

- 220 Volt (v)

- 99 %

- 800 Kilograms (kg)

- 30 - 50 BPM

- Automatic

- New

- 40-60 Pcs/min

- Bottle Cap Sealing

- 1000*800*2200 Millimeter (mm)

Automatic Multi Head Screw Cap Sealing Machine Trade Information

- 1 Piece Per Month

- 1 Week

- All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

Product Description

Automatic Multi Head Screw Cap Sealing Machine

Automatic rotary multi head cap sealing Machine is versatile, self-supported on stainless steel structures. The machine is precision built with rotary head with drives for sealing. The unit is made compact, versatile and enclosed in stainless steel finish body. Main drive of the machine, conveyor drive & cap-feeding bowl consist of motor with synchronized variable Drive and No container No Sealing system arrangement.

Containers are feeds from filling machine or unscrambler and moves on SS Slat conveyor and star wheel bringing the container below the sealing head in the subsequent indexing part, mean while the bottle pickup a cap from the delivery chute of cap feeding bowl, where the body and the neck of the container are positioned below the rotating head, where the sealing head is performing perfect operation of threading & sealing and move container further process for inspection, labeling or packing.

High-Speed & Reliable Performance

Achieve unparalleled throughput with this automatic screw cap sealing machineideal for medium to large-scale operations. With a production capacity of up to 60 bottles per minute and a 99% accuracy rate, it ensures swift and flawless capping for every batch, significantly reducing downtime and maximizing productivity.

Advanced Automatic Operation

Experience seamless and intelligent processing with full automation. The multi-head design allows simultaneous capping on multiple bottles, reducing manual labor and eliminating the chances of human error. Its user-friendly interface further simplifies operation, making it accessible even for non-technical staff.

Versatile Industry Uses

Perfect for pharmaceutical, beverage, cosmetic, and chemical industries, this sealing machine accommodates a wide variety of bottle types. Its robust construction and adjustable settings make it a suitable choice for businesses involved in bottling and packaging, boosting both efficiency and product quality.

FAQs of Automatic Multi Head Screw Cap Sealing Machine:

Q: How does the Automatic Multi Head Screw Cap Sealing Machine operate?

A: The machine utilizes multiple sealing heads to automatically secure screw caps onto bottles. Bottles are fed into the system and the heads simultaneously seal multiple bottles per cycle, streamlining the capping process without manual intervention.Q: What types of bottles can this machine seal?

A: This sealing machine is versatile and can accommodate various bottle shapes and sizes commonly used in industries like pharmaceuticals, beverages, cosmetics, and chemicals. Adjustments can be made for different bottle heights and cap sizes.Q: When should I consider using this machine over manual sealing methods?

A: Businesses aiming to improve throughput, accuracy, and consistency in their capping process should consider this machine. It is especially beneficial when handling large production volumes or when consistent cap sealing is critical for product integrity.Q: Where is this machine manufactured and available?

A: The Automatic Multi Head Screw Cap Sealing Machine is manufactured and supplied in India, available through exporters, manufacturers, producers, retailers, service providers, traders, and wholesalers.Q: What is the process for maintaining this machine to ensure optimal performance?

A: Routine maintenance involves regular cleaning, inspection of moving parts, and timely lubrication according to the manufacturers instructions. Ensuring all electrical connections and settings are correct will keep the machine running smoothly.Q: How does automatic cap sealing benefit production lines?

A: Automatic sealing enhances productivity by reducing manual labor, accelerating the capping process, and providing a high degree of accuracy. This leads to fewer errors, cost savings, and improved quality assurance for the packaged products.Q: What are the electrical requirements and installation conditions?

A: The machine operates on standard 220 Volt power supply and requires a stable, leveled installation space with dimensions accommodating its 1000*800*2200 mm size and 800 kg weight. Proper ventilation and access for maintenance are recommended.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese